PROPOSED PACKAGING FROM ALITA

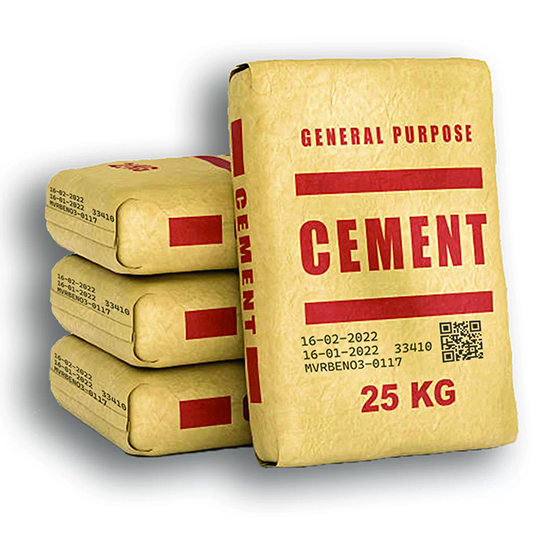

Being in the business for years, we know what one wants and how that need can be satisfied because when people talk about quantity, we focus on quality. That is why Knack Packaging has gained trust across industries. Efficient and sustainable packing materials play an essential role in the packaging of types of cement, and we have clients who rely on us for their packaging solutions. We manufacture the BOPP laminated PP woven bags in the range of 5kg to 50kg category and two variants of handle bags – the Open mouth bottom stitched bags and Open Mouth bottom-gusseted bags in the 5kg and 10kg category. Last but not least, we provide the specialized block bottom bags in the 25kg category, which comes with the valve & it is the best suited for the cement and wall putty.

We customize single and multi-layer coatings and produce sound packaging for various types of cements.

We customize single and multi-layer coatings and produce sound packaging for various types of cements. Having one of the most extensive facilities in the country, we make sure that we manufacture cost-effective packaging systems.

Having one of the most extensive facilities in the country, we make sure that we manufacture cost-effective packaging systems. Our high durability packaging reduces your product loss from damages, tears, or spills. Moreover, its leak-proof property defends the materials from moisture.

Our high durability packaging reduces your product loss from damages, tears, or spills. Moreover, its leak-proof property defends the materials from moisture.

These materials related to building including cement can date back to 400 B.C. Structures such as dams, bridges, canals, and roads have been around since pre-history of around some thousands of years. Initially, buildings were constructed out of perishable materials such as branches, animal hides, and leaves. With time new elements were introduced, like clay, timber, and stone. Later came the age of concrete and bricks. With the advent of the industrial revolution, metals and steel came into the picture. These were considered as a revolution in the field of architecture. Today, we can see various buildings made of concrete, wood, bricks, glass, and steel.

Grey cement

Grey cement (or standard Portland Cement) is probably among the most crucial elements utilized in construction. Its materials comprise elevated levels of manganese oxide and iron oxide. Its contaminants are fine than that cement. It consumes less energy when compared with snowy cement. It’s affordable. Grey cement is utilized to build high-rise properties, dams, bridges and industrial and residential complexes.

White Cement

Portland White cement, as the name implies, is a white cement. It differs from standard Portland cement being high priced, more elegant, and lighter. There is a high demand for white cement for construction material for construction in warmer states because more heat is reflected. This could be a basis for India being the 5th largest white glue producer with approximately one metric ton produced each year.

Cement Paint

Cement Paint is otherwise known as concrete paint; cement paint is durable and water-resistant. The principal ingredients of the color are all Portland cement, lime, and some pigments. Besides this, this paint includes accelerators, fungicides, fillers, and water repellents. It comes in the shape of a powder that’s combined with water.

Cement is a binding material which makes a bond between construction aggregates and reinforce them together. With the development of technology, quality and types of cement have also developed. It is one of the vital materials utilized for construction, such as offices, houses, shops, etc. Other most commonly used building materials are metals, bricks, concrete, clay, and construction aggregates, etc. At times, even the naturally occurring substances, such as sand, wood, rocks, twigs, and leaves, are used as building materials instead of cement. The cement industry is renowned worldwide. The core of any project related to construction depends on designs and the kind of materials used. The materials used for construction have played an integral role in human evolution and standards of living.